HYDRONIC SYSTEMS

Pressurised Closed Expansion, Pressurisation pumping unit/skid, Air dirt separator system, Vaccum degassing system are the integral equipment’s in Hydronic Systems. The ideal fluid in a hydronic system in heating or cooling system is water without any impurities, air bubbles or dissolved gases such as oxygen and nitrogen. However, every hydronic system starts out with air in all of its components. A well-planned system will quickly enable this air to be gathered and removed from the system. It will also reduce the dissolved air gases in the water to levels where they are of no concern with help of Air separator & pressurisation tank. The system should then maintain the water at a very low level of dissolved air content over its entire life. Any small amounts of air that may enter the system during component maintenance should be quickly captured and ejected

Advantages of Hydronic System:

- Removes dissolved gas & microbubbles and even dissolved completely.

- Removes dissolved gas & microbubbles and even dissolved completely.

- Prevents water hammering, stabilizes pressure variation.

- Ensures positive pressure throughout the system thus preventing vapour/air locks.

- Maintains constant water flow even at the most weak points in water supply system.

- Eliminates corrosion in piping and sludge formation.

- Increases the heat transfer efficiency.

- Longer service life of heating and cooling systems.

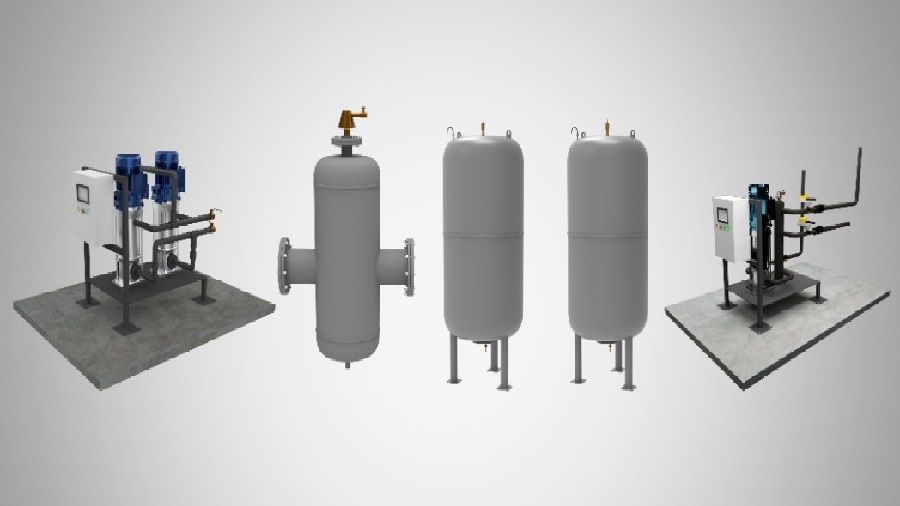

PRESSURISATION PUMPING SKID (PPS)™

PRESSURISATION PUMPING SKID (PPS)TM is an engineered packaged unit designed to replace water that has been lost through system leakage and to maintain the system design fill pressure in sealed heating and chilled water systems. A basic pressurisation unit may include Bladder Expansion Tank, Pump and Controller. A skid mounted unit may include several equipment such as pumps, control panel, pressure transmitter, bladder expansion tank, storage vessel w/ level switch, valves, controls & instrumentations, etc.

AIR & DIRT SEPARATOR (ADS)™

Our range of separators are designed to automatically remove air & dirt from heating, cooling and process systems, ensuring optimum performance of your system at all times. This product should be installed in all new buildings and can be retro-fitted into existing systems to provide economic and environmental benefits. Separators should be installed in any sizeable open or closed loop system, including chilled water systems, condenser water systems, and process water systems.

PRESSURISED CLOSED EXPANSION TANK (PCET)™ & UNPRESSURISED CLOSED EXPANSION TANK (UPCET)™

In closed heating and cooling systems, it is suitable for use an expansion tank to compensate for the increase and decrease in the volume of the water due to the temperature variation. It is suitable for use as pressure storage and shock damping tank. In this way, by reducing the number of system switching, the energy consumption decreases and the comfort level increases. At the same time, shocks and pressure fluctuations in the system can be dampened. Our range varies, capacities from 24 liters to 4000 liters. Produced as standard 10 bar operating pressure. It is suitable for use at water temperatures between

VACUUM DEGASSER SYSTEM (VDS)™

The air that is trapped inside HVAC systems is one of the main causes of system failures and inefficiencies. Removing dissolved gasses is essential for HVAC system health. The dissolved gases in water, mainly oxygen, nitrogen, and carbon dioxide, will compromise water quality. They must be eliminated quickly and effectively. Regular replenishment of freshwater inside of the system will continuously add more dissolved gasses to the system.

Applications

Airports

Business Centres

Commercial Complexes

Hospitals

Hotels

More

Certificates