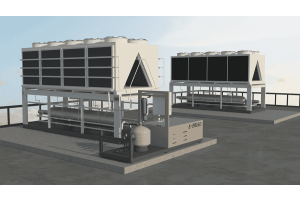

For water cooling tower systems to run smoothly, effective heat removal is essential. Water is a universal solvent that, due to its capacity to dissolve and hold large concentrations of minerals and deposits, serves as a good medium for heat transmission in cooling towers. However, the water must be treated on a regular basis to eliminate dissolved impurities, otherwise it may cause scaling, fouling, and corrosion in the cooling tower. As a result, heat transmission is reduced, and the cooling tower becomes inefficient. As a result, chemical water treatments are required to eliminate harmful mineral particles and prevent microbial development.

A solid, complete cooling tower water treatment system may help you save money on maintenance, water, and energy. It can also help you limit the frequency of blowdown or cooling tower leak by using high-quality makeup water. There are several other types of water cooling towers in the market that can match these requirements, but their effectiveness is doubtful. The most frequent approach is chemical treatment, which uses oxidizing and non-oxidizing biocide to create a protective chemical layer to prevent biological fouling and deposits. However, there are certain disadvantages to using dangerous chemicals to treat your cooling tower water. Chemicals are dangerous in terms of its handling & proper EH'S Compliance is required which increases the operational challenges & cost. Chemical water cooling tower treatment products are extremely costly and must be acquired on a regular basis because they do not provide a permanent solution. In addition to the potential of unintentional hazardous contamination, the risk increases during the water treatment process. The advancement of purification techniques has resulted in a significant increase in the number of chemicals used: chlorine, lime, iron chloride, soda, bleach, various flocculating agents, sulphuric acid, and methanol, which increases the risk of chemical reaction following ocular or cutaneous exposure. That is why chemical-free cooling tower water treatment is

critical for mitigating these concerns.

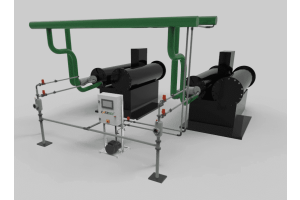

Introducing Electrochemical Treatment System (ECTS)™: A Non-chemical water treatment for Cooling Tower solution to remove Scale, Corrosion and Bio-Fouling from the system.

Understanding the need of the hour, EnerGeo® offers a compelling reason to adopt a sustainable green-technology that processes cooling tower water in an ecologically acceptable manner. ECTS™ is a completely automated online system that treats the cooling tower water without the use of any chemicals. Electrochemical Treatment System (ECTS)™ is a safest technology available that treats the water with Zero Chemical use & saves money on operations and extends equipment life while also contributing to a more sustainable future. By removing harmful water treatment chemicals, it instantly minimizes the environmental footprint and enhances your savings. The primary concerns for all organizations in today’s time is to adopt a suitable future which ensures cost-effectiveness, energy savings, water conservation & green environment and Electrochemical Treatment System (ECTS)™ is the product meeting the sustainable goals.

The benefits of ECTS™ include:

- Elimination of all chemical expenditures

- Significant water and energy savings.

- Maintenance and downtime are drastically reduced.

- Reduces the blowdown requirements by 50-70%.

Electrochemical Treatment System or Water Cooling Tower System should be your go-to

option for a more sustainable future, with the sole purpose of offering building owners and

facility managers with an eco-friendly alternative for generating operational savings.

OUR TOP PRODUCTS:

Adiabatic Cooling System | Electrolytic Scale Remover | Automatic Tube Cleaning System | Vacuum Degasser system | Air & Dirt Separator |

Anti Fouling Condenser System | Closed Expansion Tank | Hydronic Systems