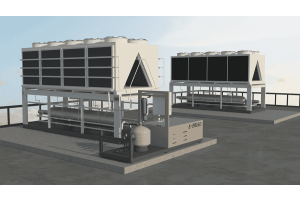

Water is used in evaporative cooling systems, such as cooling towers, to remove excess heat in a range of structures and institutions. An Electrochemical Treatment System with side stream filtration may make a major difference in the performance of these cooling towers, whether they are utilized for an industrial/process or comfort air conditioning. While it is easy to neglect preventative measures and maintenance systems, a side stream filtration system is your cooling tower's first line of defense against a wide range of problems. Solid buildups, airborne debris, and pollen have the ability to clog and perhaps halt the interior working of any cooling tower water treatment system if not filtered. This form of scaling and fouling also allows bacteria like Legionella to flourish.

An Electrochemical Treatment System with side stream filtration eliminates suspended and settled particles, which can enhance energy efficiency of your chiller plantroom by supplying leaving water temperature from the cooling tower at lower/optimum level by eliminating operational losses. The following are the primary reasons why cooling tower water treatment (Non-Chemical) makes sense:

1. Reduced blockage and downtime

With the right type of system, particulate matter, biological growth, and suspended materials are removed from cooling tower water. It will also help to eliminate solid deposits in the cooling tower and obstructions in heat exchangers, tubes, and other key process equipment. As a result, your cooling system's operating efficiency will increase, with less unscheduled downtime.

2. Increase equipment life

Solid buildups of dirt particles, precipitates, and biological deposits in cooling water may necessitate more cleaning and maintenance cycles. This, when combined with scaling and fouling, may cause damage to your cooling tower equipment. Filtering suspended particles and bacteria from cooling tower water is therefore a simple preventive measure that will help to extend the life of your equipment.

3. Conserve water and chemicals

Minerals in unfiltered water can cause blowdown in cooling towers. This lost water must then be restored, which might take hundreds of gallons. An excellent system

may help you decrease blowdown and boost water savings by filtering out those particles. It can reduce your dependency on water treatment chemicals to treat your cooling towers by reducing scaling and biofouling.

4. Reduce maintenance and energy costs

By installing the system, you may save a substantial amount of money on energy and maintenance. Less accumulation in cooling towers implies less cleaning time. Cleaner water in cooling towers with fewer deposits necessitates less reactive maintenance in the long run. Furthermore, a well-maintained cooling tower will continue to operate at peak efficiency, lowering energy expenses.

5. Improve operational efficiency

A cooling tower that is filled with unclean water cannot function properly. All of that accumulation clogs tubes and coats heat transfer surfaces, requiring the cooling

system to work harder. An effective side stream filtering system not only reduces deposits but also improves the efficiency of the corrosion inhibitor used.

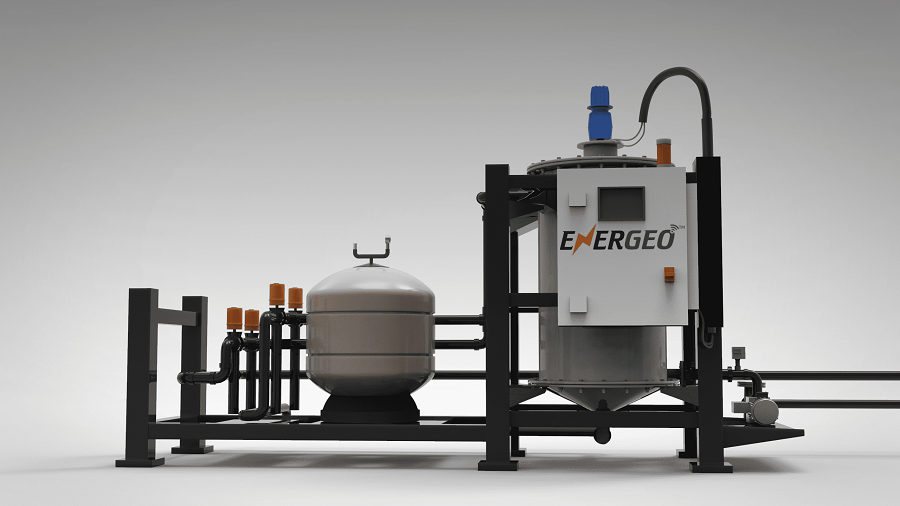

Conclusion: An Electrochemical Treatment System with side stream filtration is an essential component of a cooling tower water treatment programme which enhances the cooling tower effectiveness, saves blowdown water by upto 50-70%, Zero Chemicals required hence Environment friendly & improves chiller performance by operational losses.

OUR TOP PRODUCTS:

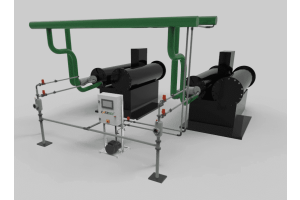

Adiabatic Cooling System | Electrolytic Scale Remover | Automatic Tube Cleaning System | Vacuum Degasser system | Air & Dirt Separator |

Anti Fouling Condenser System | Closed Expansion Tank | Hydronic Systems