Fouling in shell and tube heat exchangers may be unavoidable, for all we know. But have you ever considered the consequences of this fouling? Let's take a closer look! Once started, fouling in heat exchangers grows in thickness, eventually reducing heat transfer performance. This, in turn, prevents adequate heat transmission and extends the operating hours of Chillers. This might result in a loss of corporate profitability since it increases spending on energy bills and decreases revenues due to output loss.

So, what is the solution to all of this?

The solution is straightforward: automatic tube cleaning system or automatic condenser cleaning system. Regardless of your industry – chemical production, HVAC, refinery process, or power plant – an automatic tube cleaning system or an automatic condenser cleaning system is a proven and established solution that will undoubtedly work for you!

What is the big deal about automatic tube cleaning systems or automatic condenser

cleaning systems? So, let us go through some of the advantages that this method

provides.

- It can save you up to 20% on your energy expenditures.

- Restore the heat exchangers' original cooling capability.

- Reduces production losses and downtime.

- Increase the life of your equipment by more than 20%.

- Reduce the expense of upkeep.

- Increase the power output, especially if you are talking about a power plant.

How quickly do automatic tube cleaning systems or automatic condenser cleaning

systems pay for themselves?

Yes, indeed! In reality, most of the time, the cost of establishing the system is recouped in a couple of months or a year at most. Often, the system pays for itself in less than a year. In certain circumstances, the investment is recouped in a few months by avoiding a forced shutdown and reducing output loss.

So, how do automatic tube cleaning systems or automatic condenser cleaning systems

operate?

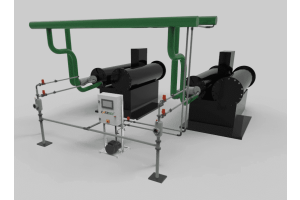

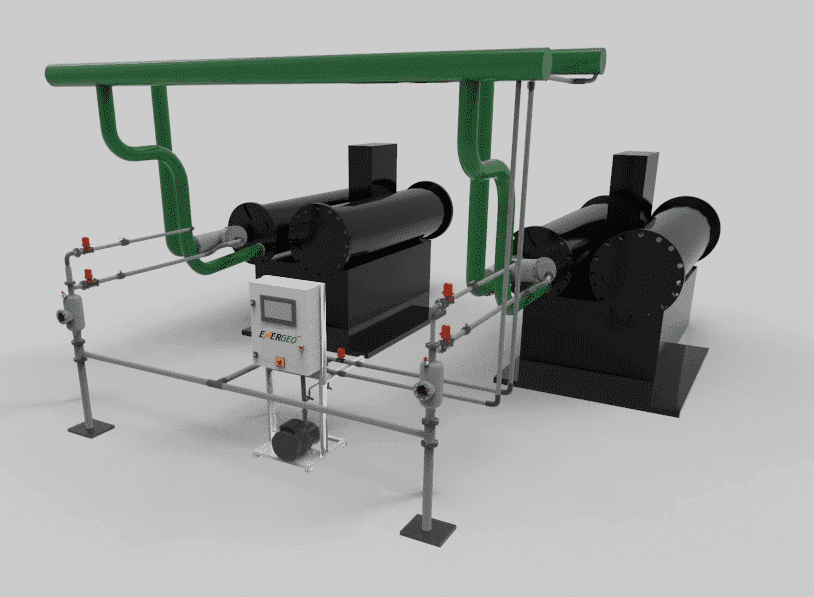

The automatic tube cleaning systems or automatic condenser cleaning systems offered by EnerGeo® are made up of specialized balls that are infused into the cooling water flow at regular intervals. While cleaning the tubes, the balls move through them and are collected at the outlet. After that, they are ready for the subsequent cleaning cycle. Ball traps come in a variety of forms and flow patterns, depending on the available space and pipe runs.

What is it that makes automatic tube cleaning systems or automatic condenser cleaning

systems worthwhile?

To begin, you may rest certain that no process shutdowns will be required. Furthermore, with automatic tube cleaning systems or automatic condenser cleaning systems, your plant will be free of any chemicals used in the cleaning process, freeing you of any labour linked to the disposal of such chemicals. However, we give a guarantee of zero lost balls, guaranteeing that you get excellent value for your money.

We are certain that now that you are aware of some of the outstanding benefits of automatic tube cleaning systems or automatic condenser cleaning systems, you will quickly implement the same for the maintenance of your shell and tube type heat exchangers.

Get an estimate of your energy savings. Please provide us with your equipment's tonnage, kilowatt per ton, local power cost, and projected load hours. You can contact us by email at support@energeo.in or by phone at (+91) 8055 556 698. We will answer quickly with an estimate of energy savings and price.

OUR TOP PRODUCTS:

Adiabatic Cooling System | Electrolytic Scale Remover | Automatic Tube Cleaning System | Vacuum Degasser system | Air & Dirt Separator |

Anti Fouling Condenser System | Closed Expansion Tank | Hydronic Systems